Efficient Eco-friendly Farming System with Improved Fish Welfare

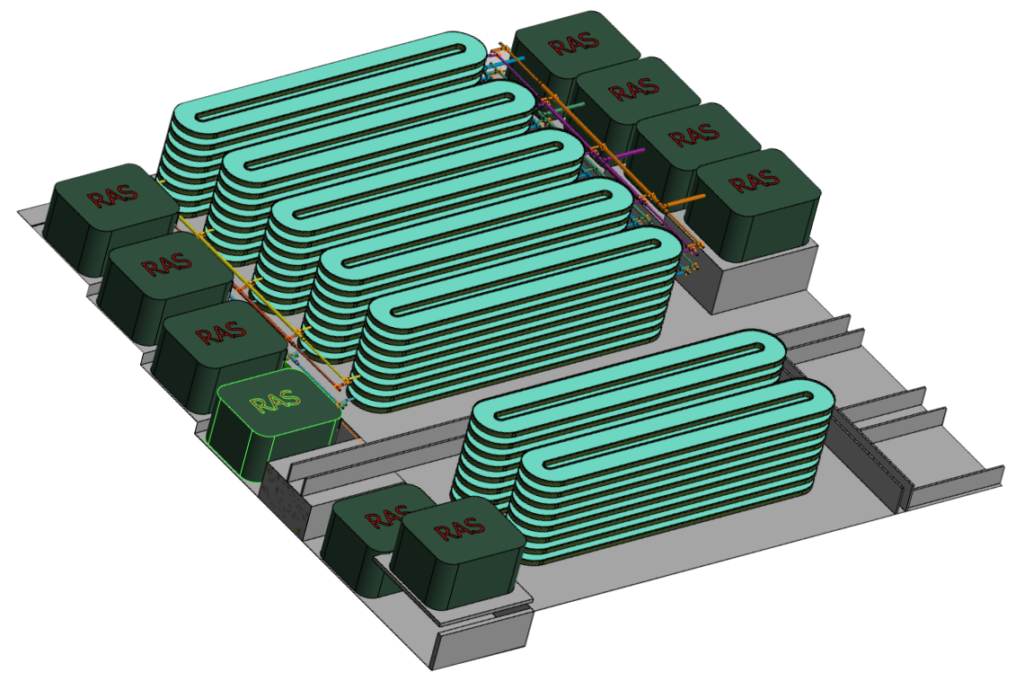

Fish is farmed in animal-friendly vertical raceways, allowing for higher fish densities than other land-based fish farms.

Supported by Innovation Norway

FARMING ON LAND IN SHALLOW VERTICAL RACEWAYS

Discover Our Vertical Fishfarm

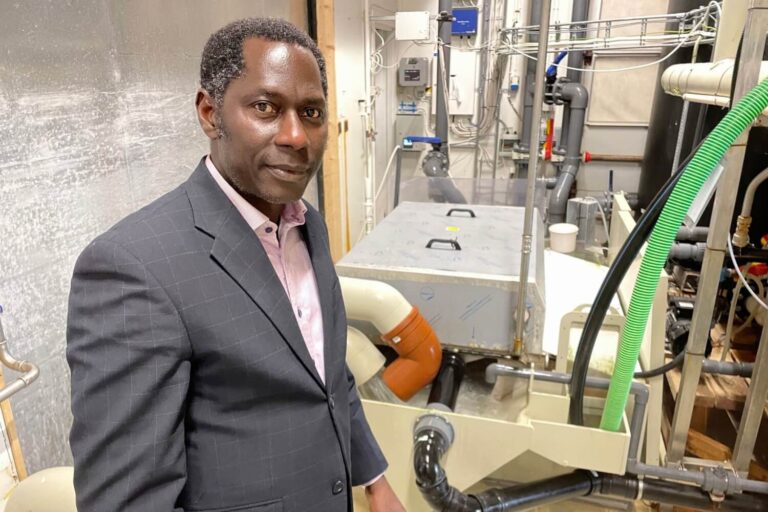

SIFT Group is a Norwegian company that has developed a unique, innovative land-based fish farming concept based on Super-Intensive Farming Technology (SIFT). The fish are grown in raceways connected to a freshwater or saltwater refreshing RAS (Recycling Aquaculture System). The concept has previously been thoroughly tested through research and industrial sole and turbot aquaculture. It has now been tested in a three pilot farm phases for Atlantic salmon in Tromsø. The proven concept is now ready for the commercial phase build up – supported by Innovation Norway.

Supported by Innovation Norway

Advantages and Uniqueness of Our Technology

Swimming continuously upstream up to 50 km in the raceways, our salmon has robust, muscular, lean meat with a fat content that tastes like wild salmon, which should fetch premium market prices.

A simple way of understanding fish-welfare is through mortality rates: We are proud to have practically near zero mortalities. The shallow raceways offer optimal current speed for a given fish species. Intensive swimming improves the heart muscles and health of farmed fish. Oxygenation with nanobubbles and the intelligent waste removal system improve animal welfare further. An inbuilt disinfection system reduces the risk of disease outbreaks and fish lice problems.

Aerobic and anaerobic biofilters reduce the need for make-up water and subsequent environmental discharge. The waste volume is recycled into bioenergy and possible manure for agriculture. The unique vertical farming set-up is adaptable for Aquaponic production.

The standard farming unit is a SIFT Cell comprising five raceways and one RAS. This cell is the building block in a vertical farming setup that can be combined horizontally and vertically, like a Lego system. It optimizes space utilization, reduces the risk of infections and bacterial spread from one cell to the rest of the farm, and reduces most pumping to horizontal circulation. Additionally, this unique configuration is highly effective in managing and reducing risks at every level of multi-story vertical farming.

Productivity and profitability are increased. In the Pilot farm, we succeeded in growing fish at standard growth curves at 200 kg per m3, double that of traditional land-based farms, with almost no disease-related mortality and without compromising fish welfare.The feed conversion ratio (FCR) was 0.7-0.8 – 30% lower than that of other land-based salmon farms, conveyed by constantly feeding with floating pellets in the shallow raceways.The vertical farming system minimizes land use and the need for water pumping and temperature regulation, thus reducing energy consumption by 50% compared to other land-based farms. The operational costs (OpEx) for farming salmon in a SIFT system are estimated to be comparable to farming salmon in open ocean net pens.

SIFT Group continuously invests in the development of our aquaculture technology. This ensures profitability and leadership in sustainability, efficiency, and animal welfare.

Optimal growth

Fish is farmed in a high-density environment at an optimum temperature unique for the species, combined with proper lighting in terms of circadian rhythm, colour selection, and intensity.

Biosecurity

SIFT provides opportunities for refreshing all water from emissions before circulation to the environment and lowers the risk of bacterial and viral infection applied from the environment, and protects from sea lice infection.

Farming Environment

Short crop cycle in a water recirculation aquaculture system (RAS) with optimal oxygen levels and removal of growth inhibitors like CO2 and nitrogen. Self-cleaning vertical raceways reduce pathogen contamination.

Operational Simplicity

All raceways and associated equipment are accessible for both visual and physical control. A computer manages the entire farming system.

The Sustainable Development Goals (SDGs), also known as the Global Goals, were adopted by all United Nations Member States in 2015 as a universal call to action to end poverty, protect the planet and ensure that all people enjoy peace and prosperity by 2030. You can take part in our sustainable contribution to fish farming.

“By 2025, prevent and significantly reduce marine pollution of all kinds, particularly from land-based activities, including marine debris and nutrient pollution”.

Goal 14.1

Latest Articles

News articles about us and our technology.